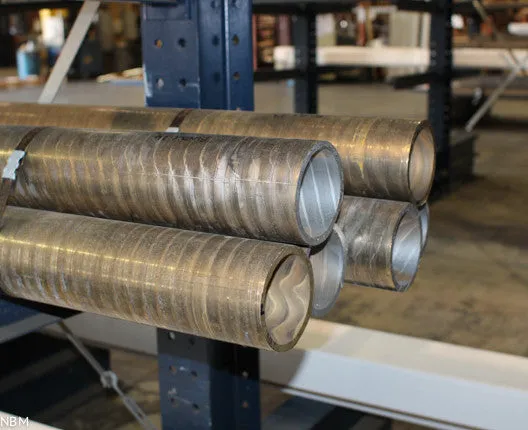

Typical Uses for C91100 Tin Bronze:

ELECTRICAL: Hollow Conductors

INDUSTRIAL: Piston Rings, Bushings, Bearings

| Al | Sb | Cu | Fe | Pb | Ni | P | Si | S | Sn | Zn | |

| Min/Max | 0.005 | 0.2 | 82.0 - 85.0 | 0.25 | 0.25 | 0.5 | 1 | 0.005 | 0.05 | 15.0 - 17.0 | 0.25 |

| Nominals | - | - | 83.5000 | - | - | - | - | - | - | 16.0000 | - |

| Product Type | Temper Type |

| Continuous | ASTM B505 |

| Ingot | ASTM B30 |

| Sand | ASTM B22 |

| Temper | Sect. Size | Cold Work | Type Min | Temp | Tensile Strength | YS 0.05% UL | YS 0.02% Offset | YS 0.005% Offset | Elong. | RH B | RH C | RH F | RH 30T | VH 500 | BH 500 | BH 3000 | Shear Strgth | Fatigue Strgth | Izod Impact Strgth |

| - | in. | % | - | F | ksi | ksi | ksi | ksi | % | B | C | F | 30T | 500 | 500 | 3000 | ksi | ksi | ft-lb |

| - | mm. | - | - | C | MPa | MPa | MPa | MPa | - | - | - | - | - | - | - | - | MPa | MPa | J |

| As Continous Cast | |||||||||||||||||||

| M07 | 68 | 55 | 30 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M07 | 0 | SMIN | 20 | 379 | 207 | - | - | - | - | - | - | - | - | - | - | - | - | 0 | |

| As Sand Cast | |||||||||||||||||||

| M01 | 68 | 35 | 25 | - | - | - | - | - | - | - | - | - | 135 | - | - | ||||

| M01 | 0 | TYP | 20 | 241 | 172 | - | - | 2 | - | - | - | - | - | - | 135 | - | - | 0 |

| Product Property | US Customary | Metric |

| Joining Technique | Suitability |

| Brazing | Good |

| Coated Metal Arc Welding | Fair |

| Gas Shielded Arc Welding | Fair |

| Machinability Rating | 10 |

| Oxyacetylene Welding | Fair |

| Soldering | Excellent |

| End Product | Specification |

| Continuous | ASTM B505 |

| Ingot | ASTM B30 |

| Sand | ASTM B22 |